With the development trend of paper box packaging gradually replacing plastic packaging. High speed, high precision automatic die-cutting machine is favored by users. In the automatic die cutting machine, the quality of the machine is directly affected by the motion and dynamic characteristics of the paper feeding mechanism. Common problems are as follows: First, automatic die cutting machine layout pressure uneven Automatic die cutting machine layout pressure, this adjustment will just show the cutting edge does not lubricate, hair, burst line problems. The pressure adjustment of the layout should be gradually pressurized from small to large, should be small and should not be large, to make the pressure accepted by the layout common, to get the pressure of ambition, to press out the proof for inspection, and then constantly adjust. Second, the die-cutting precision of automatic die-cutting machine is not high The die-cutting blade of the automatic die-cutting machine is also a major factor, and the problems caused by it are not high die-cutting accuracy, the cutting edge is not lubricated, and the hair is raised. Die cutter must choose the appropriate type and standard of excellent products in order to prevent the occurrence of various situations in the future use process. Three, automatic die-cutting machine rubber strip has occurred paste board The adhesive strip will form a die cutting plate and paste plate, affecting the speed and quality. There are also tricks in the selection of rubber strips, low hardness is selected on both sides of the embedded line, and the blade height of the rubber strip is 2 mm; Narrow local application of high hardness, 0.5 mm higher than the blade Four, automatic die-cutting machine is easy to appear indentation line irregular Indentation line In order to prevent the occurrence of irregular indentation line, excellent indentation line should be selected. Moderate hardness, strong stability, wire lubrication is necessary, and then it is necessary to select the appropriate height, thickness, and standard.

[2024-04-30]View More >

Invitation to Drupa International Printing Exhibition in Germany

[2024-04-28]View More >

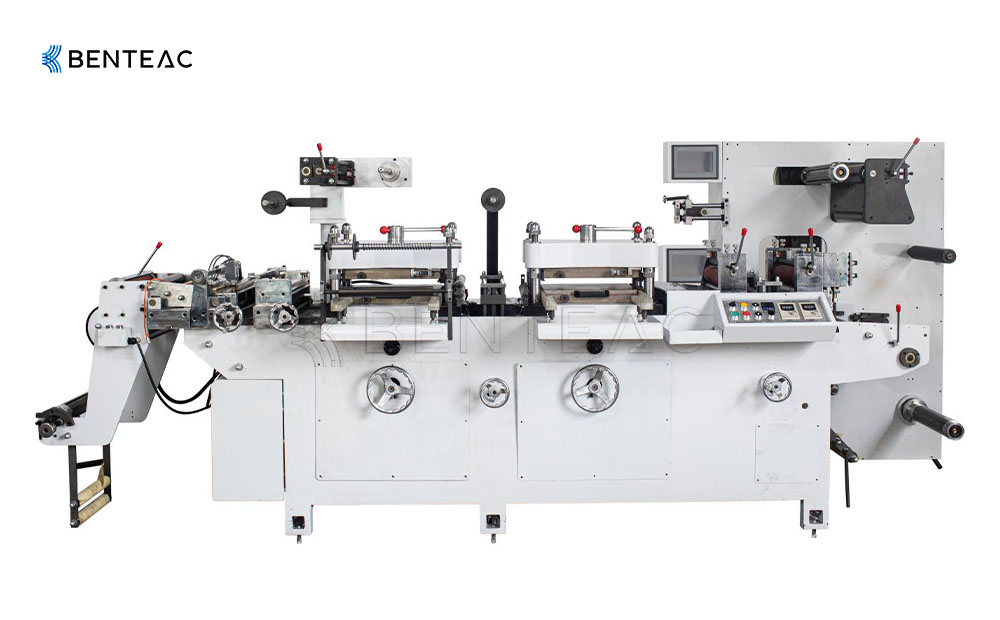

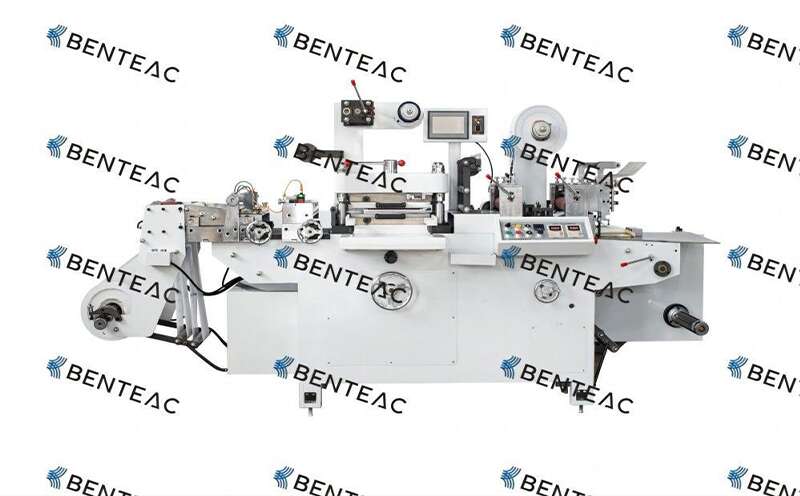

Application range of self-adhesive die cutting machine: First, insulation EMI: aluminum foil, copper foil, PVC, PET, kraft paper, sponge sheath, pearl sheath and so on. Second, electronic industry: electrical special rubber pads, silicone stickers, Velcro, conductive adhesive, strong double-sided adhesive, 3M, SONY special adhesive, backlight screen electronics industry, IT industry film switch, automotive manufacturing and processing industry used in adhesive products, etc. Third, dustproof materials: cosmetic cotton, camera cotton, high-density sponge, filter cotton, dust screen, non-woven fabric and so on. Four, shockproof products: rebound rubber pad, rubber, transparent foot pad, PORON pad, 3M, flame retardant EVA, high foaming and so on. Fifth, heat resistant insulation materials: silicon film, transparent mica sheet, fiber cloth, heat insulation cotton (cloth) and so on. Self-adhesive die cutting machine also has the following characteristics: First, it can be applied to a variety of roll, sheet material bonding/stamping applications Second, mainly through the use of computer servo CNC system to pull, feed, can be made full break, half break punch, waste, high precision, low noise, fast speed, with anti-scratch function. Third, it is possible to achieve the characteristics of two die cutting punching, which is widely used in the electronics industry and printing industry. Can also be customized according to customer requirements of the secondary positioning die cutting function.

[2024-04-12]View More >

Self-adhesive die cutting machine is also called numerical control die cutting machine, widely used computer die cutting machine is also called numerical control die cutting machine, relative to the previous drawbar die cutting machine and the most original punch faster, full touch screen operation, more convenient operation, make products with higher precision and higher efficiency. Self-adhesive die cutting machine is through the way of up and down stamping in advance according to the product drawings of the good die die stamping into a certain shape, the whole die cutting machine operation process is through Yaskawa servo motor to drive the automatic feeding machine feeding, through the feeding to complete the film, and then through the die cutting machine die base punching, and finally discharge the border waste, cut into pieces to complete the whole process. High precision die-cutting, dragging and slicing are controlled by computer with flat pressing. The printing label is accurately tracked and positioned by three photoelectric eyes on both sides and longitudinal. The roll used for die-cutting, laminating, waste collection, slicing or automatic labeling machine is completed at one time. It is very suitable for die-cutting of paper self-adhesive trademarks, polyester film trademarks and laser anti-counterfeiting trademarks. This machine is the best supporting equipment for flexographic printing machine, continuous screen printing machine, gravure printing machine and anti-counterfeiting trademark molding machine, which is the most ideal and efficient trademark printing factory. Self-adhesive die-cutting machine is mainly used in a variety of special-shaped trademark die-cutting, such as all kinds of beer labels, food and beverage labels, and can be widely used in cutting various sizes of playing cards, tags, envelopes, aluminum-plastic bags, New Year cards, face and toilet covers, notebooks, credit cards, brochures, and a variety of special shapes of children's book cards and books.

[2024-04-06]View More >

Die cutting machine is divided into circular die cutting machine, circular die cutting machine, flat die cutting machine and so on

[2024-04-06]View More >

The kraft paper made by our common kraft paper bag machine is generally yellowish brown, and it is often used to make bags and wrapping paper. There are many types of kraft paper on the market. According to the nature and use of kraft paper, we can often classify it. According to different classifications, it will be easier for us to find the kraft paper we need.

[2022-06-27]View More >

Paper bag machines often have some problems, we need to understand the reasons for these problems. If there is an error in the length of the cut bag, we need to lock the rubber roller, and then check whether the film is clamped in the rubber roller. Secondly, we need to observe whether the feeding speed is too high. If it is too high, we need to reduce the feeding speed in time.

[2022-06-27]View More >

In today’s era where everyone pays attention to hygiene, we can see that many friends who cook food will use some very environmentally friendly and healthy packaging, because now people are very particular about eating, so there are many good food My friends, they also hope that they can satisfy me with the best packaging, so that they can have a better business. So we can see that there are many businesses now, they will use some very environmentally friendly paper bags as the packaging materials.

[2022-06-27]View More >

In fact, when every kind of food is marketed, it is hoped that it will have unique brand advantages. Of course, this must be designed in the packaging process for its manufacturer or related introduction, so that it can be sold in the food market. The marketing value brought by time will be higher and higher. Among them, after the sharp-bottomed paper bag is designed, there will be more and more features in the food factory. In terms of brand design creativity, it is felt that there will be more and more highlights.

[2022-06-27]View More >

We participate in different international printing exhibitions every year. In addition to communicating with new and old customers at the exhibition, it also allows us to understand the market trends and the dynamics of competitors, and constantly improve our technology and products. To better align our business strategy and product positioning.

[2019-10-25]View More >

Ruian Maoyuan Machinery Co., Ltd. every year to participate in Belgium label packaging printing exhibition (LABELEXPO Europe) and other domestic and foreign packaging and printing industry exhibitions. In addition to communicating with new and old customers, each exhibition also shows the company's technological development in the year. Let everyone witness that Maoyuan's services and products are constantly changing and becoming better and better.

[2019-09-27]View More >