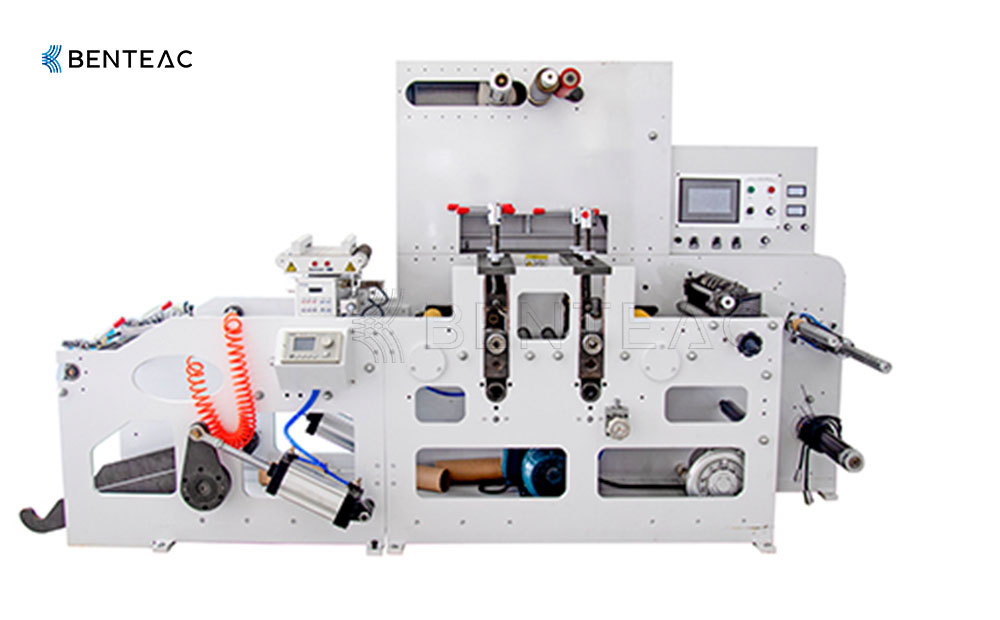

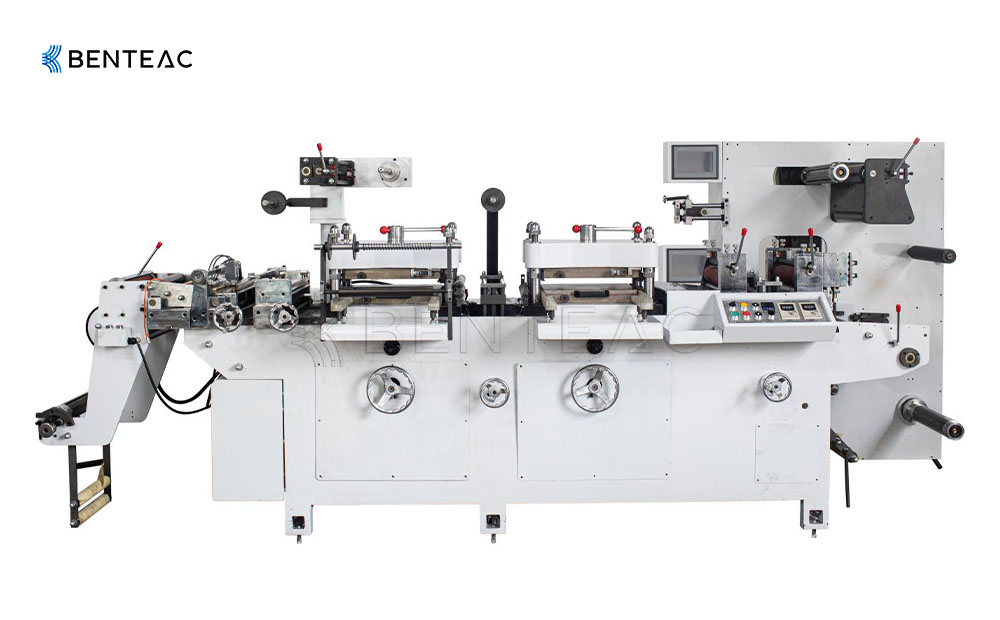

Automatic die-cutting machine has higher and higher requirements for the consistency of packaging size. Therefore, packaging and decoration printing enterprises in the batch packaging post-printing processing, it is imperative to use advanced flat press automatic die-cutting machine. Flat die cutting machine is the key equipment for printing and packaging products to improve labor productivity after printing. It is not only an efficient, safe and high-quality die cutting molding equipment, but also the replacement of "tiger" products, which is favored by the majority of packaging and printing enterprises. The wide application and broad market prospects of this equipment, automatic die-cutting machine has attracted many equipment manufacturing enterprises. At present, China's flat press automatic die-cutting machine has formed a complete series of varieties, anti-static floor, in technology has also reached a higher level. In order to improve the work efficiency and product grade of the flat press automatic die cutting machine, the enterprise should also carry out the technical transformation of the die cutting equipment, and the row knife of the die cutting template should also carry out the technical transformation of the automatic die cutting machine. The future development trend of automatic die-cutting machine is mainly reflected in the following three aspects. Automation, intelligent, multi-functional automatic die-cutting machine automation, intelligent level will be further improved. Automatic loading and unloading device, automatic waste removal device will be more and more perfect; Automatic die-cutting machine equipment functions are increasingly diversified, both die-cutting, but also hot printing, but also hot printing holographic marks. The further development of high-speed, efficient and high-precision machine manufacturing technology and electrical control technology will promote the further improvement of the speed and accuracy of the automatic die-cutting machine.

[2024-05-06]View More>

With the development trend of paper box packaging gradually replacing plastic packaging. High speed, high precision automatic die-cutting machine is favored by users. In the automatic die cutting machine, the quality of the machine is directly affected by the motion and dynamic characteristics of the paper feeding mechanism. Common problems are as follows: First, automatic die cutting machine layout pressure uneven Automatic die cutting machine layout pressure, this adjustment will just show the cutting edge does not lubricate, hair, burst line problems. The pressure adjustment of the layout should be gradually pressurized from small to large, should be small and should not be large, to make the pressure accepted by the layout common, to get the pressure of ambition, to press out the proof for inspection, and then constantly adjust. Second, the die-cutting precision of automatic die-cutting machine is not high The die-cutting blade of the automatic die-cutting machine is also a major factor, and the problems caused by it are not high die-cutting accuracy, the cutting edge is not lubricated, and the hair is raised. Die cutter must choose the appropriate type and standard of excellent products in order to prevent the occurrence of various situations in the future use process. Three, automatic die-cutting machine rubber strip has occurred paste board The adhesive strip will form a die cutting plate and paste plate, affecting the speed and quality. There are also tricks in the selection of rubber strips, low hardness is selected on both sides of the embedded line, and the blade height of the rubber strip is 2 mm; Narrow local application of high hardness, 0.5 mm higher than the blade Four, automatic die-cutting machine is easy to appear indentation line irregular Indentation line In order to prevent the occurrence of irregular indentation line, excellent indentation line should be selected. Moderate hardness, strong stability, wire lubrication is necessary, and then it is necessary to select the appropriate height, thickness, and standard.

[2024-04-30]View More>

The kraft paper made by our common kraft paper bag machine is generally yellowish brown, and it is often used to make bags and wrapping paper. There are many types of kraft paper on the market. According to the nature and use of kraft paper, we can often classify it. According to different classifications, it will be easier for us to find the kraft paper we need.

[2022-06-27]View More>

Paper bag machines often have some problems, we need to understand the reasons for these problems. If there is an error in the length of the cut bag, we need to lock the rubber roller, and then check whether the film is clamped in the rubber roller. Secondly, we need to observe whether the feeding speed is too high. If it is too high, we need to reduce the feeding speed in time.

[2022-06-27]View More>

In today’s era where everyone pays attention to hygiene, we can see that many friends who cook food will use some very environmentally friendly and healthy packaging, because now people are very particular about eating, so there are many good food My friends, they also hope that they can satisfy me with the best packaging, so that they can have a better business. So we can see that there are many businesses now, they will use some very environmentally friendly paper bags as the packaging materials.

[2022-06-27]View More>

In fact, when every kind of food is marketed, it is hoped that it will have unique brand advantages. Of course, this must be designed in the packaging process for its manufacturer or related introduction, so that it can be sold in the food market. The marketing value brought by time will be higher and higher. Among them, after the sharp-bottomed paper bag is designed, there will be more and more features in the food factory. In terms of brand design creativity, it is felt that there will be more and more highlights.

[2022-06-27]View More>