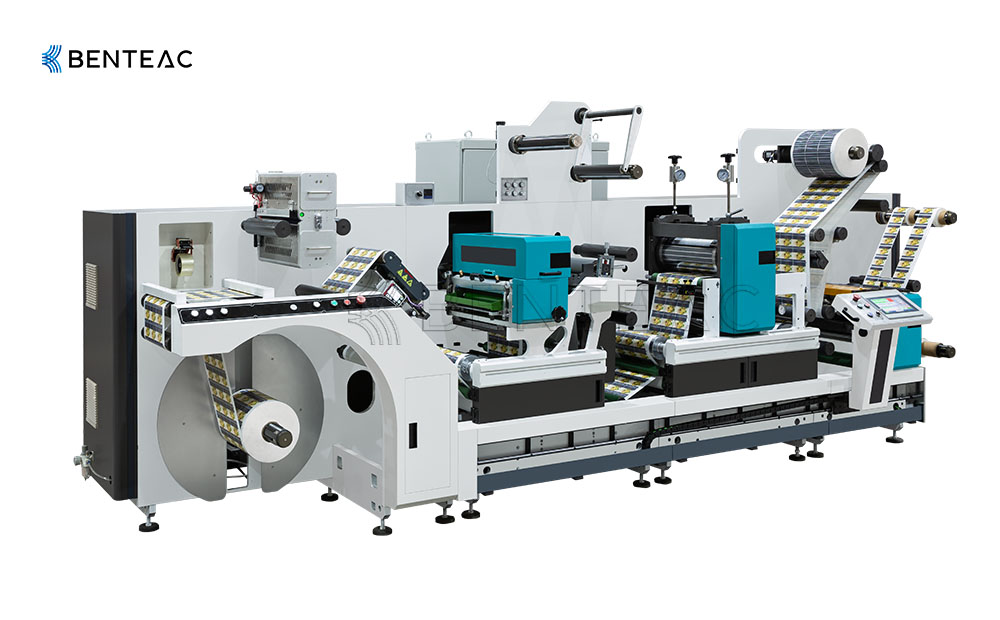

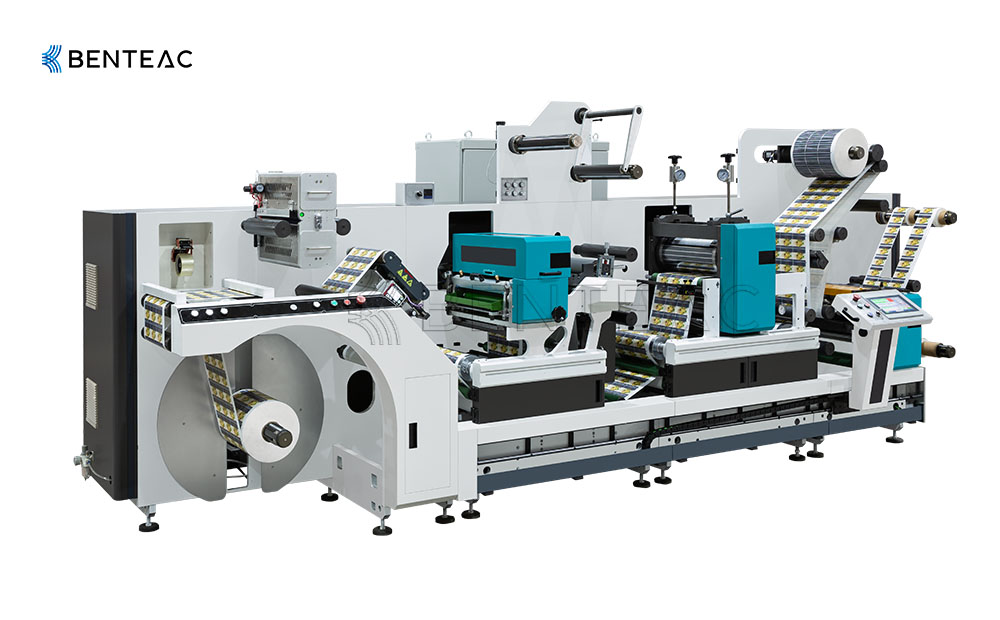

Application field of rotary label die-cutting machine: offline (offline) die-cutting processing after printing of self-adhesive labels, and centralized processing of the printed self-adhesive materials with secondary registration and alignment of circular knife rotary die-cutting, waste discharge, stripping, and finished product winding.

The rotary label die-cutting machine is for the roll label materials such as printed self-adhesive labels (battery labels, medical labels, food labels), and performs centralized processing of secondary registration and alignment of rotary die-cutting, waste discharge, stripping, and finished product winding. It is particularly suitable for the centralized processing of label products with a single specification and large batches and long-running products with repeated orders, reflecting the advantages of high efficiency and high quality post-printing processing of self-adhesive labels. It effectively solves the bottleneck phenomenon of post-printing die-cutting processing of label printing enterprises, and is an ideal choice for centralized post-printing processing of printed labels to improve product die-cutting quality, increase production capacity, and reduce production and operation costs.

1. Wide range of applications: It can die-cut various shapes of single-sided and double-sided self-adhesive stickers, protective films, gaskets, dust-proof nets, copper and aluminum foils and other products. These products are widely used in the post-printing die-cutting of front and rear shells, windows, displays, microphones, receivers, keyboards, batteries and other parts of electronic products such as mobile phones, laptops, PDAs, digital cameras, and audio equipment, as well as labels. Especially for multi-layer composite products, the one-time molding effect is particularly obvious.

2. Flexibility: Each axis on the production line can be set as a raw material axis, a waste axis or a finished product axis; it can be started and stopped at any time; the direction of rotation can be changed at any time. The cantilever tension sensor is more convenient to disassemble and move. The exquisitely designed die-cutting workstation is more practical than the ordinary printing line; each workstation can change the working direction or stop working at any time; each die-cutting workstation can adjust the tool registration manually or automatically.

3. Accurate and stable registration: All axes are controlled by sensitive tension sensors, and the tension of each retracting and unwinding axis can be set and the tension is constant; each workstation is equipped with an automatic registration system and the registration is accurate and stable whether manual or automatic.

4. High efficiency: The maximum speed can reach 60 meters/minute, and the output value is very high.

5. Servo drive: Each die-cutting workstation is driven by a servo system. All raw materials and waste are driven by a servo system.

6. Tension control: All axes are equipped with a constant tension control system.

7. Automatic calibration: The automatic calibration system can automatically adjust the mold on each workstation.