Product Introduction:

Automatic rolling punching machine is widely used in printing, packaging, paper products and other industries. Microcomputer, man-machine control interface, servo positioning, AC frequency converter, manual pneumatic lock plate, photoelectric correction system, centralized lubrication. The machine has the characteristics of compact structure, fast speed, high efficiency, accurate cutting, simple operation and stable operation.

Product Introduction:

Automatic rolling punching machine is widely used in printing, packaging, paper products and other industries. Microcomputer, man-machine control interface, servo positioning, AC frequency converter, manual pneumatic lock plate, photoelectric correction system, centralized lubrication. The machine has the characteristics of compact structure, fast speed, high efficiency, accurate cutting, simple operation and stable operation.

The main machine configuration:

1、Unwinding device: 3 inch (diameter 76.2mm) Air expansion shaft 1 set, auto tension control

2、Using the starting brake control system, the unwinding tension control is stable.

3、Web Guiding System (Edge Correction system, Line Correction System)

1)Use electric actuators

2)Adopt rectifying photoelectric sensor for rectifying transmission

3)Correction Accurancy: ±0.05mm

4、Traction System: it is controlled by frequency control, it can control the unwinding speed and tension effectively.

5、Dancing Roller: Servo controls the dancing rollers which can control the tension during the intermittent moviment.

6、Servo Swing Roller: it ensures the smooth operation of the line rectifying system.

7、Servo Traction: Servo controls the paper feeding cylinder, and ensures that mould can punch the products smoothly and accurately. The paper feeding cylinder is controlled by two cylinders, and the air pressure is balanced.

8、Color Sensor: it gurantees the high precision by folowwing the marks.

9、The punching power adopts high-strength steel heat treatment, triangular belt drive, and it is equipped with flywheel structure. The main motor adopts 3.7kw frequency conversion control, with low energy consumption and high efficiency, ensuring high speed and stable power output.

Specification:

|

Model Type |

GW-CLB500 |

|

Max Paper diameter |

φ800mm |

|

Punching Speed |

100 – 200 strokes/min |

|

Punching Accuracy |

±0.25mm |

|

Paper Gsm |

60-120g/m2, Thickness: ≥0.06mm (aluminum foil, laminated paper, plain aluminum) |

|

Max paper max-width='100%' width |

490mm |

|

Max Punching Dimension |

460*300mm |

|

Servo Motor / Frequency Converter / PLC |

Schneider |

|

Total Power |

10KW |

|

Weight |

4000kg |

|

Dimension |

Around 3800x1900x1800mm |

|

Country of Origin |

China |

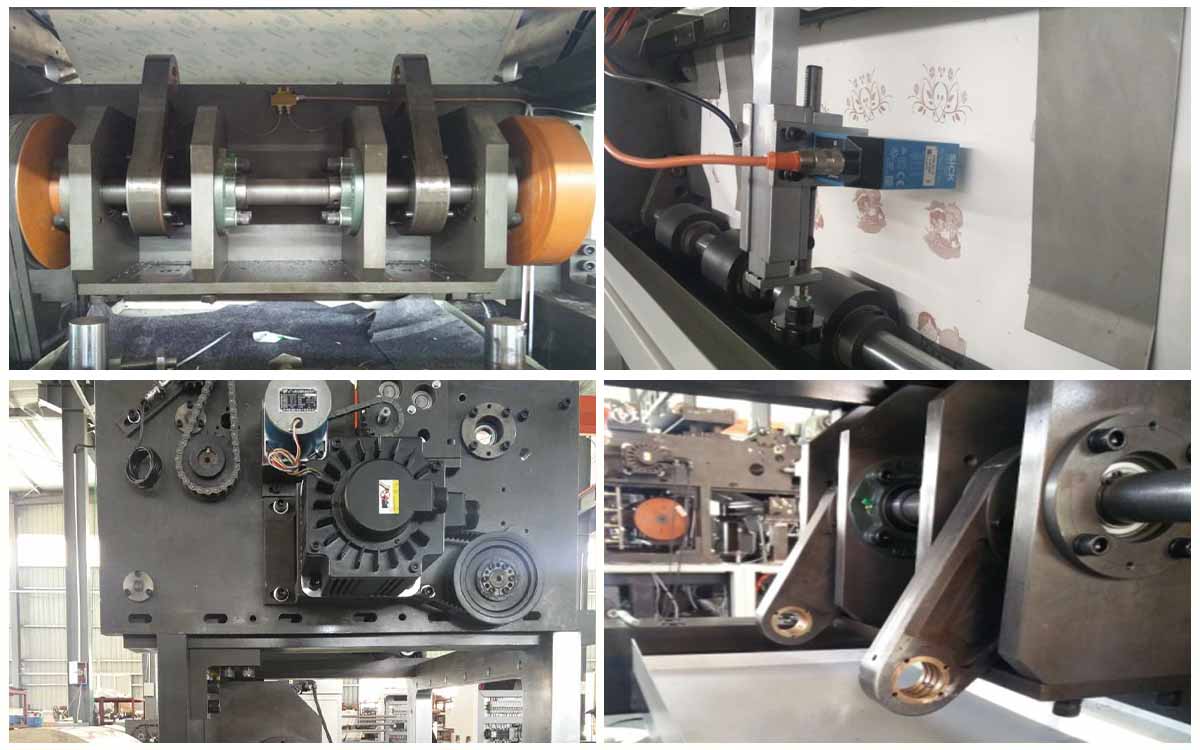

Machine Detail Pictures:

Main feature: 1. High-speed operation, making paper products roll-cutting, die-cutting and removing waste products become a process. Effectively improve raw material utilization rate and finished product rate. 2. According to the paper layout, use different shapes of cutter heads to pneumatically lock the cutter heads for easy replacement. 3. The paper feed double-row rubber rollers move randomly and move synchronously. The air feed improves the paper feed function. 4. Directly cut the roll paper to reduce waste, the waste paper rate is lower than ordinary film cutting machine. 5. Sturdy structure, easy to operate. 6. Fully automatic, reduce manpower.

Product Introduction: Automatic rolling punching machine is widely used in printing, packaging, paper products and other industries. Microcomputer, man-machine control interface, servo positioning, AC frequency converter, manual pneumatic lock plate, photoelectric correction system, centralized lubrication. The machine has the characteristics of compact structure, fast speed, high efficiency, accurate cutting, simple operation and stable operation.

Welcome to our website! Please feel free to send us your questions by asking us, we will contact you and provide you with the services as soon as possible.