Smart design, adapt to almost all customer site needs

Refined process, can be operated without professional training

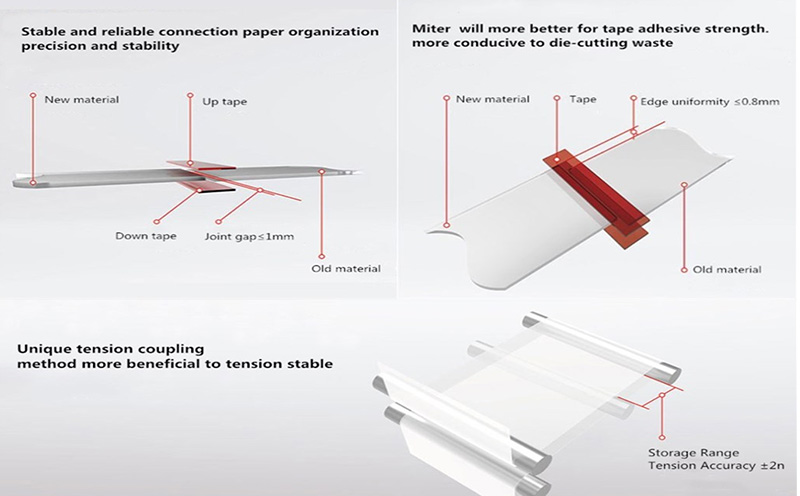

Stable and reliable machine installation

Automatic inflation shaft

Lifelong maintenance-free inflatable shaft

Stable tension control system, with segmented tension coupling calculation technology

100% paper splicing success rate

Adhesive tape on both sides

Can be connected to die cutting and other downstream processing

Three kinds of automatic unwinding die-cutting are optional: manual unwinding mode, roll diameter setting mode and paper finishing mode.

Full self-correcting function of winding belt

Laser positioning of splicing material edge alignment

Brief Introduction:

Smart design, adapt to almost all customer site needs

Refined process, can be operated without professional training

Stable and reliable machine installation

Automatic inflation shaft

Lifelong maintenance-free inflatable shaft

Stable tension control system, with segmented tension coupling calculation technology

100% paper splicing success rate

Adhesive tape on both sides

Can be connected to die cutting and other downstream processing

Three kinds of automatic unwinding die-cutting are optional: manual unwinding mode, roll diameter setting mode and paper finishing mode.

Full self-correcting function of winding belt

Laser positioning of splicing material edge alignment

|

Model: |

HAUS/550 |

Explanation: Simple operation, no need to have any signal or cable connection with the host, even if the host emergency stop, jog, lift, speed reduction, etc., the unwinding machine can be stable without stopping. Note: Special materials need to be confirmed by Choyu Machinery Co., Ltd. to avoid burrs or continuous cutting when cutting materials, such as warp-weft synthetic paper, wrapping film and other thin films.

|

|

Name |

Non-stop unwinder |

|

|

Maximum Material max-width='100%' width |

550mm |

|

|

Maximum Machine speed |

100 M / min |

|

|

Maximum Unwinding diameter |

φ850mm |

|

|

Unwinding |

Zero speed docking (adhesive tape on both sides) |

|

|

Unwinding tension accuracy |

±2% |

|

|

Unwinding mode |

Roll diameter mode + manual mode |

|

|

Unrolling and receiving success rate |

100% |

|

|

Power |

8kw |

|

|

Machine footprint |

2700mm(Long)×2350mm(High) |

|

|

Machine weight |

1.8 Ton |

|

|

Applicable materials |

40-400g paper, double transparent stickers, PE sheet, etc. |

|

|

Feeding way |

Left to right from the operation surface |

Sample drawing:

Smart design, adapt to almost all customer site needs Refined process, can be operated without professional training Stable and reliable machine installation Automatic inflation shaft Lifelong maintenance-free inflatable shaft Stable tension control system, with segmented tension coupling calculation technology 100% paper splicing success rate Adhesive tape on both sides Can be connected to die cutting and other downstream processing Three kinds of automatic unwinding die-cutting are optional: manual unwinding mode, roll diameter setting mode and paper finishing mode. Full self-correcting function of winding belt Laser positioning of splicing material edge alignment

Features: 1. The rewinder can be connected with printing presses, die cutters, slitting machines and other equipment, from paper tube loading to rewinding, and then to unloading. 2. Equipped with inflatable shaft storage point: the inflatable shaft can be exchanged conveniently. The air expansion shafts are 1 inch, 1.5 inches, and 3 inches. 3. Change the size of different rolls, no manual mechanical adjustment is required, and the touch screen of different sizes can be adjusted automatically 4. Paper tube vibration plate: It can effectively reduce labor intensity, improve efficiency, and realize intelligent production.

Welcome to our website! Please feel free to send us your questions by asking us, we will contact you and provide you with the services as soon as possible.