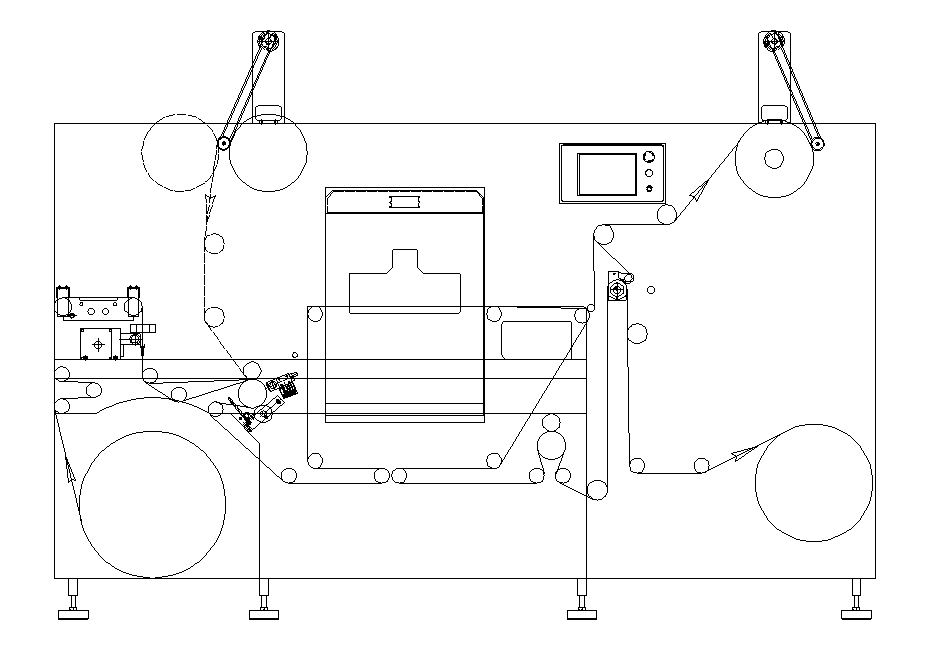

Unwind-Max unwind dia.700mm; Air expanding mandrel 3"

Web guide-Maxcess Web guide ( Edge position control )

Flat bed die cutting-Eye mark sensor, height of the blade 9.5mm ( with upper blade and the bottom blade )

Rewind-Single rewind, Max unwind dia.700mm; Air expanding mandrel 3"

Waste matrix-Max unwind dia.600mm; Air expanding mandrel 3"

|

NO. |

Purchase Items included in the offer |

UNIT |

|

1 |

Unwind-Max unwind dia.700mm; Air expanding mandrel 3" |

1 |

|

2 |

Web guide-Maxcess Web guide ( Edge position control ) |

1 |

|

3 |

Flat bed die cutting-Eye mark sensor, height of the blade 9.5mm ( with upper blade and the bottom blade ) |

1 |

|

4 |

Rewind-Single rewind, Max unwind dia.700mm; Air expanding mandrel 3" |

1 |

|

5 |

Waste matrix-Max unwind dia.600mm; Air expanding mandrel 3" |

1 |

Parameter:

|

1 |

Max Speed |

400 repeats/min |

|

2 |

Accuracy of Cutting |

±0.15mm |

|

3 |

Max Machine Web Width |

330mm |

|

4 |

Min slitting max-width='100%' width (Option) |

16mm |

|

5 |

Max Unwinding Dia. |

φ700mm |

|

6 |

Max Rewinding Dia. |

Φ700mm |

|

7 |

Total Machine Consumable |

14KW |

|

8 |

Overall Diameter(L×W×H) |

2700mm×1300mm×1500mm |

|

9 |

Weight |

3000KG |

|

10 |

Power Supply |

AV,380V,50HZ |

|

11 |

Air Supply |

0.4~0.6 MPa |

Web Path:

It uses an accurate rotary die-cutting system and performs material conversion through micro-control. Die cutting, waste rewinding and finished product rewinding are all in one process. Main control PLC and man-machine interface, with functions such as edge detection and watch detection. The cutting system uses magnetic powder clutch and magnetic powder brake to control the synchronization of cutter and die cutting. Separate waste motor control.

1. Mother reel end photocell with automatic stop. 2. Full rotary flexo printing module support sport varnishing/cold foil 3. Die cut unit able to work full rotary mode and semi rotary mode. 4. Precision cutting to reduce waste

Unwind-Max unwind dia.700mm; Air expanding mandrel 3" Web guide-Maxcess Web guide ( Edge position control ) Flat bed die cutting-Eye mark sensor, height of the blade 9.5mm ( with upper blade and the bottom blade ) Rewind-Single rewind, Max unwind dia.700mm; Air expanding mandrel 3" Waste matrix-Max unwind dia.600mm; Air expanding mandrel 3"

It uses an accurate rotary die-cutting system and performs material conversion through micro-control. Die cutting, waste rewinding and finished product rewinding are all in one process. Main control PLC and man-machine interface, with functions such as edge detection and watch detection. The cutting system uses magnetic powder clutch and magnetic powder brake to control the synchronization of cutter and die cutting. Separate waste motor control.

Приветствуем вас к нашему сайту! Отправите нам ваши справки в любое время по следующей форме, мы будем связывать с вами, предоставляем вам соответственное обслуживание так быстрее, как лучше, заполните пожалуйста по-английски.